How to Reduce Manufacturing Waste? – Material and Packaging Waste

Manufacturing is the backbone of modern economies, but it also carries an environmental cost. The production process often generates waste, from excess raw materials to discarded packaging. This waste not only harms the environment but also eats into a manufacturer’s bottom line. Fortunately, there are a multitude of strategies that manufacturers can implement to reduce waste and create a more sustainable and efficient operation. Here, we will see how to reduce material waste and packaging waste in manufacturing.

Table of Contents

What Is Manufacturing Waste?

Manufacturing waste is the material or resources discarded or not used in manufacturing, including excess raw materials, broken or defective products, scrap materials, and energy or water used in production. It has negative environmental and economic impacts, and thus manufacturers aim to reduce manufacturing waste and boost efficiency and sustainability. Lean manufacturing has greatly altered how we see waste in making things by cutting down waste and showing what is valuable.

The first step towards waste reduction is understanding where it originates. Manufacturers can achieve this clarity through a waste audit. This comprehensive analysis involves meticulously identifying, quantifying, and characterizing the waste streams generated throughout the production process. By pinpointing the areas that create the most waste, manufacturers can target their efforts for maximum impact.

Types of Manufacturing Waste

Knowing and identifying the types of manufacturing waste helps in reducing manufacturing waste. The different types of lean waste are classified as:

- Overproduction – Producing more than what is needed to store it.

- Waiting – Bottlenecks in the production, including idle workers and machines.

- Transport – Moving products and parts multiple times.

- Processing – Unnecessary processing steps in the process of production.

- Inventory – Overstocking supplies leading to manufacturing overheads.

- Motion – Unnecessary movement of people, machines, or equipment due to inefficient workflows.

- Correction – Utilizing a process that produces a lot of scraps or defective products.

In lean manufacturing, not using full potential is seen as the eighth kind of waste. The hardest waste to reduce is not fully using your workers’ skills.

Also Read: Waste Management: Principles, Methods and Benefits.

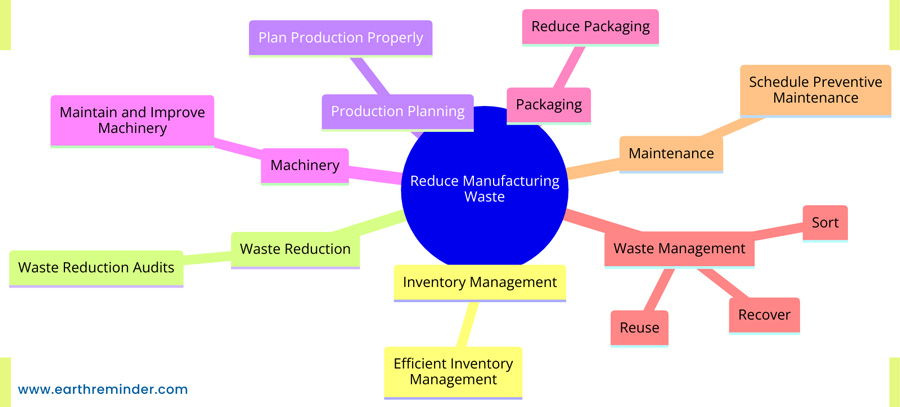

7 Effective Tips to Reduce Manufacturing Waste

Mapping out your manufacturing waste stream and classifying the types of manufacturing waste is the first step. Once you have done that, you can move on to the various ways of reducing manufacturing waste.

Efficient Inventory Management

It can be challenging to eliminate excess stock. Maintaining a certain stock level requires complete inventory control. Expired products can slow down your orders and work. A good system to manage your stock can help use your products before they expire.

Waste Reduction Audits

Audits target equipment usage and potential improvements. For example, checking for less waste can find parts that break easily getting worn out more. Because the way workers use machines matters too, they need to keep learning, including that on recycling equipment such as industrial trash compactors and industrial trash chutes to safely and conveniently remove debris and waste from the work area. Not using machines as suggested can make them work too hard and damage the delicate parts. A tough year with many workers leaving can result in not enough people who know how to use big machines correctly. This can greatly reduce work output if machines stop working because they were not used right.

Outside observation and honest assessments can provide the management with ideas previously not considered. They may suggest a full-scope audit not conducted promptly or suggest improvements to the line. Information about what is happening on the floor can lead to noticeable improvements and influence high-level thinking.

Plan Production Properly

All factory owners aim to lower the time workers are not doing anything and possibly reduce the hours needed for making products. Though there are moments when having fewer workers is better, as the time when employees are not busy can be used to increase productivity in other areas.

Line workers and engineers can be trained as amateur techs to maintain and evaluate the line. It is far less expensive to repurpose employees with a small pay bump than to hire a third party or a new full-time employee for a singular task.

Plan production around items that will sell as well. Under utilizing materials accumulates manufacturing waste, including that in development, clouding the product’s purpose with too many features and complicating sales. Lean manufacturing aims to produce a product that fulfills needs while thinking granularly about the approach.

Also Read: 3 R’s of Environment: Reduce, Reuse, and Recycle.

Maintain and Improve Machinery

Lubricants keep the machine running smoothly and avoid unnecessary tears on fragile parts. Maintaining machinery at regular intervals will help you spot a problem before it goes out of hand. While each machine has its own maintenance plan, some parts, like power units, need a special schedule. Run seal tests and rain checks on objects encountering high-powered torque and test new parts to prevent expensive problems.

Reduce Packaging

Focus on durable or reusable products to reduce manufacturing waste. Though product packaging makes it attractive, it is also one of the most significant contributors to manufacturing waste. Cut down packaging to only necessary and also encourage your suppliers to do the same.

Redesign your product packaging to ensure minimum use of products. For example, using air packs for cushioning in packaging can be a way to achieve a lifestyle with no waste. Reuse the cardboard boxes or leftover plastics used to pack your products.

Recover, Reuse, Sort

Employ techniques such as electrolysis and filtration to recover the maximum possible manufacturing waste from onsite and offsite locations. For materials like paper, plastic, and metals, recycling is a solution. Industrial shredders are vital in reducing manufacturing waste by condensing asphalt, rubber wood, and plastics to a fraction of their original size. You should avoid recycling hazardous substances as it rarely has any environmental benefits.

Sorting the types of manufacturing waste ensures it lands in the right place. Assign someone to monitor the bins to find a viable solution for eliminating, reusing, or reducing manufacturing waste. Exchange your manufacturing waste with other businesses through waste exchange programs.

Schedule Preventive Maintenance

Your production process may face avoidable delays and extra expenses for fixing machines that break down during manufacturing. A solid plan for upkeep work lets you maintain things regularly. This avoids issues and keeps the work flow smooth and continuous.

Follow these tips to reduce manufacturing waste to reduce lean time and provide competitive service with less manufacturing waste while remaining friendly to the environment.

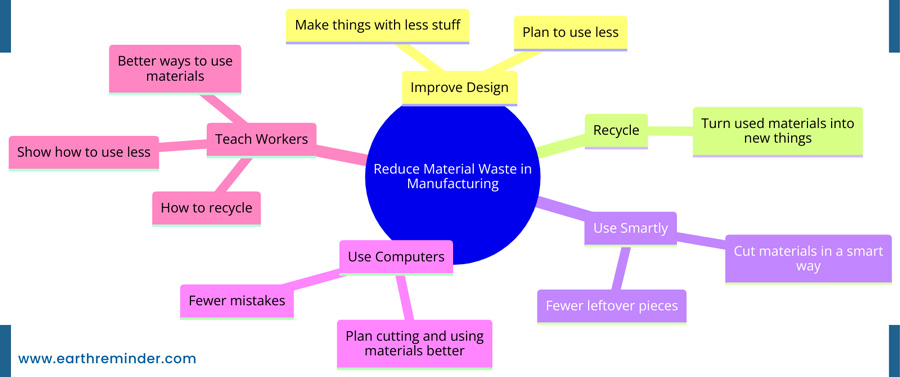

How To Reduce Material Waste in Manufacturing?

Besides above tips you can reduce material waste in manufacturing in following ways:

- Improve Design: Make things with less stuff. Plan from the start to use less, which means less waste.

- Recycle: Turn used materials into new things. This could mean taking something old and making it into something new again.

- Use Smartly: Cut materials in a smart way to use most of it. This helps in having fewer leftover pieces.

- Use Computers: Use computer programs to plan cutting and using materials better. This helps in making fewer mistakes.

- Teach Workers: Show workers how to use less and waste less. This can be about better ways to use materials and how to recycle.

Also Read: What Is the Difference Between Reuse and Recycle?

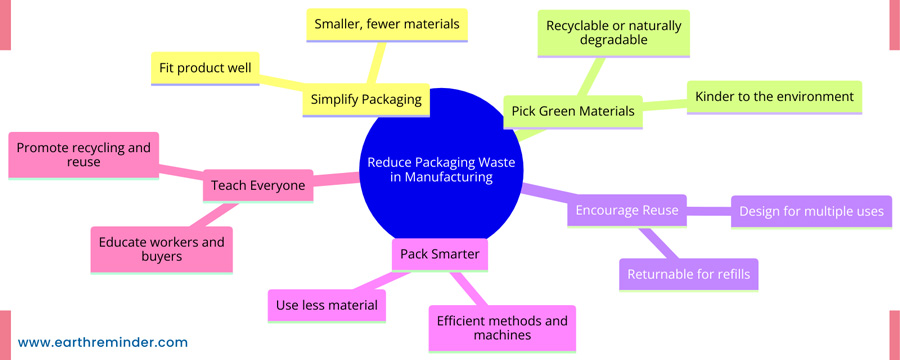

How To Reduce Packaging Waste in Manufacturing?

Below are five simple ways to cut down on packaging waste in manufacturing:

- Simplify Packaging: Make the packaging smaller and use fewer materials. Aim for designs that fit the product well without extra space or layers.

- Pick Green Materials: Use materials that are kinder to the environment, like those that can be recycled or naturally break down. This means choosing packaging that can go back into the earth or be reused.

- Encourage Reuse: Design packaging that can be used again. This could mean making packaging that’s good enough to be used for something else or can be returned to be refilled.

- Pack Smarter: Use less material when packing products. This involves using machines and methods that make the most of the packaging material without wasting it.

- Teach Everyone: Help workers and buyers know more about reducing waste. This involves showing workers how to use less packaging and telling buyers how they can recycle or reuse packaging.

In the end, to cut down waste in making and packing things, we need to start smart. Use less from the start, pick earth-friendly materials, use just what you need, and try to use things again. It’s important to teach people how to help in this. By doing this, we can use less, throw away less, and help our planet.